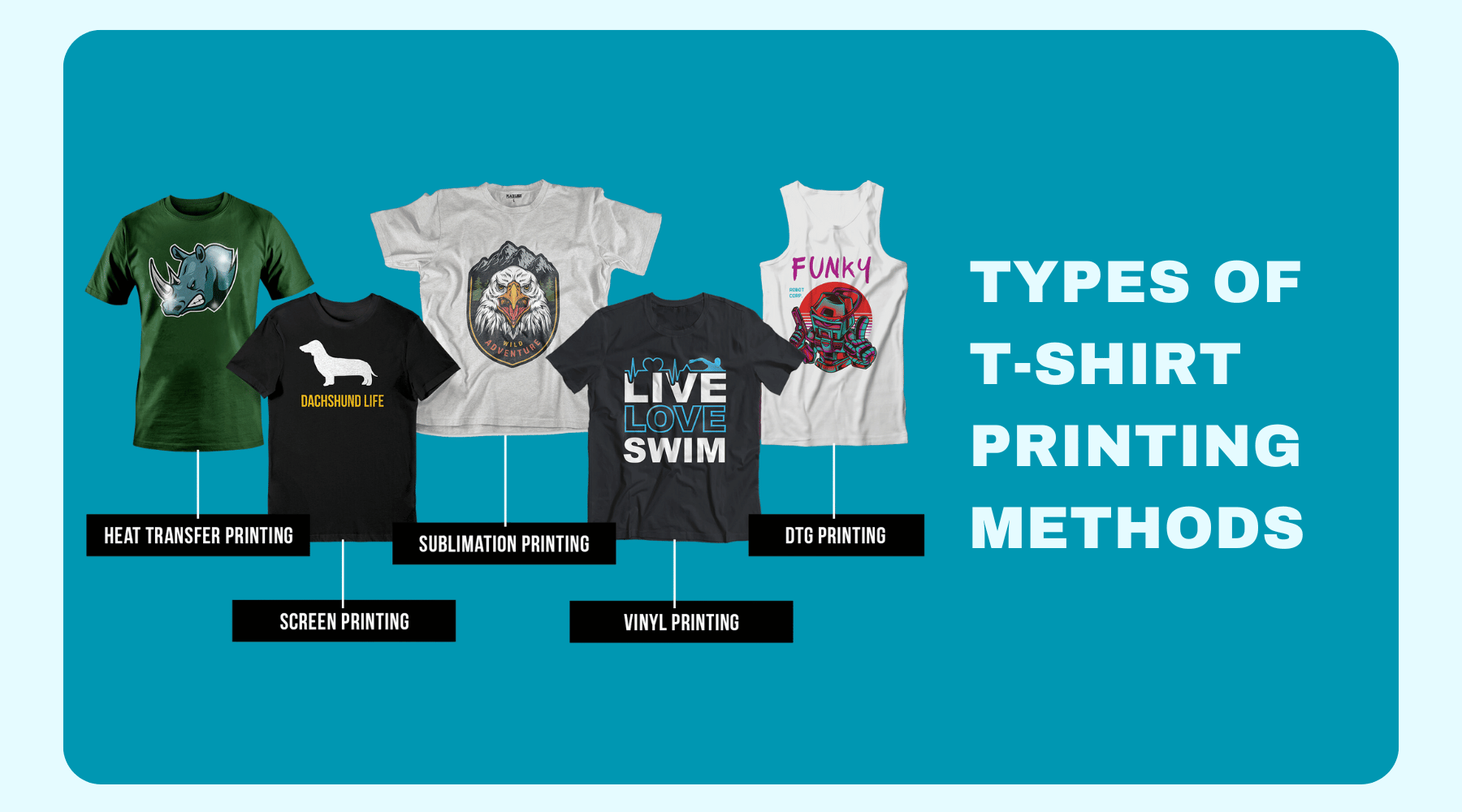

When it comes to creating custom t-shirts, the printing method you choose can significantly impact the final product's quality, durability, and cost. Whether you're starting a t-shirt business, making shirts for an event, or simply customizing your wardrobe, understanding the different types of t-shirt printing methods is essential.

In this detailed guide, we'll explore the main t-shirt printing techniques: screen printing, direct-to-garment (DTG) printing, heat transfers, and sublimation printing. We'll also discuss their pros and cons, helping you make an informed decision.

Screen Printing

Screen printing, also known as silk screening, is one of the oldest and most widely used t-shirt printing methods. This technique involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface.

How screen printing Works:

- Design Creation: The design is created digitally and then transferred onto a mesh screen coated with a light-sensitive emulsion.

- Exposure: The screen is exposed to light, hardening the emulsion and leaving the design area soft.

- Washing: The screen is washed with water, removing the soft emulsion and leaving a stencil of the design.

- Printing: The screen is placed on the t-shirt, and ink is spread over the screen using a squeegee. The ink passes through the open areas of the screen, imprinting the design onto the fabric.

- Curing:

- The printed t-shirts are then cured using heat to ensure the ink sets properly.

Also Read: Custom DTF Heat Transfer Instructions

Pros of Screen Printing:

- Durability: Screen-printed designs are highly durable and can withstand many washes without fading or cracking.

- Vibrant Colors: This method allows for bright, vivid colors that stand out.

- Cost-Effective for Bulk Orders:

- Screen printing is very economical for large quantities, as the setup costs are spread over many shirts.

Cons of Screen Printing

- Setup Time: The preparation process is time-consuming, involving multiple steps to create the screen.

- Not Ideal for Complex Designs: Screen printing is best suited for simple designs with a limited number of colors.

- Environmental Impact:

- The process uses chemicals and water, which can be harmful to the environment if not managed properly.

Direct-to-Garment (DTG) Printing

Direct-to-garment printing is a relatively new method that uses inkjet technology to print designs directly onto the fabric. It offers a lot of flexibility and is perfect for detailed and colorful designs.

How DTG Printing Works:

- Design Preparation: The design is created digitally, typically using graphic design software.

- Printing: The T-shirt is placed in a DTG printer, which directly applies the ink onto the fabric, like how a regular inkjet printer works on paper.

- Curing:

- The printed t-shirts are then cured using heat to set the ink.

Pros of DTG Printing:

- Detail and Complexity: DTG printing is capable of producing highly detailed and complex designs with a wide range of colors.

- No Setup Costs: There are no screens or stencils, making it ideal for small orders or one-offs.

- Soft Feel: The ink is absorbed by the fabric, resulting in a soft print that doesn’t feel heavy or stiff.

Cons of DTG Printing:

- Durability: DTG prints may not last as long as screen prints, especially if not properly cared for.

- Cost: More expensive for bulk orders compared to screen printing.

- Printing Speed: Slower than screen printing, making it less efficient for large orders.

Heat Transfers

Heat transfer printing involves transferring a design from a specially printed paper onto a t-shirt using heat and pressure. This method is popular for its ease of use and versatility.

How Heat Transfers Works:

- Design Creation: The design is created digitally and printed onto transfer paper using inkjet, laser printers, or specialized sublimation printers.

- Transfer Process: The printed transfer paper is placed on the t-shirt, and a heat press is used to apply heat and pressure, transferring the design from the paper to the fabric.

Also Read: DTF Printing vs. Sublimation: Which Method Should You Choose?

Pros of Heat Transfer:

- Versatility: Heat transfers can be used on a variety of fabrics and materials, including cotton, polyester, and blends.

- Detail and Color: Capable of producing detailed and vibrant designs with a wide range of colors.

- Ease of Use:

- Simple process that doesn’t require extensive setup, making it suitable for DIY projects.

Cons of Heat Transfer:

- Durability: Heat transfer designs may crack or fade after multiple washes, especially if not properly applied or cared for.

- Feel: Transfers can sometimes feel stiff or have a plastic-like texture on the fabric.

- Cost: Can be expensive for large orders due to the cost of transfer papers and inks.

Sublimation Printing

Sublimation printing is a method that uses heat to transfer dye onto materials, particularly polyester. This technique is known for producing high-quality, durable prints with vibrant colors.

How Sublimation Printing Works:

- Design Creation: The design is created digitally and printed onto special sublimation paper using sublimation ink.

- Transfer Process: The printed sublimation paper is placed on the t-shirt, and heat and pressure are applied using a heat press. The heat causes the dye to turn into gas and bond with the fabric.

- Curing:

- The printed t-shirts are allowed to cool, setting the dye into the fabric.

Pros of Sublimation Printing:

- Durability: Sublimation prints are permanent and won’t crack, fade, or peel over time.

- Feel: The print becomes part of the fabric, resulting in a smooth, soft finish.

- Detail and Color: Produces high-quality, vibrant designs that can cover the entire t-shirt.

Cons of Sublimation Printing

- Material Limitation: Sublimation works best on polyester and light-colored fabrics. It doesn’t work well on cotton or dark fabrics.

- Cost: The equipment and materials for sublimation printing can be expensive, making it less accessible for small-scale projects.

What T-shirt Printing Method Should I Choose?

So, which t-shirt printing method reigns supreme? It depends on your priorities!

- For Bulk Orders and Bold Colors: Screen printing is your champion. It's cost-effective for large quantities and delivers vibrant, long-lasting prints.

- For Small Batches and Complex Designs: DTG takes the crown. It allows for intricate designs and shines for smaller orders, although the cost per shirt might be higher.

- For Simple Designs and Personalization: Heat Transfer is your go-to. It's affordable, easy to use for one-off projects, and perfect for adding names, numbers, or logos.

- For All-Over Prints and Synthetic Fabrics:

- Dye sublimation steals the show. It creates stunning, full-coverage prints that become part of the fabric itself, but only works well on synthetic materials

Conclusion

Choosing the right t-shirt printing method depends on various factors, including the complexity of your design, the material of your t-shirt, and the size of your order. Screen printing, DTG printing, heat transfers, and sublimation printing each have their unique advantages and drawbacks. Understanding these can help you select the best method for your specific needs, ensuring your custom t-shirts come out exactly as you envision.

FAQs

Which method is best for t-shirt printing?

The best method depends on your needs. For durability and bulk orders, screen printing is ideal. For detailed and one-off designs, DTG printing is the best choice.

What is the longest-lasting t-shirt printing method?

Screen printing and sublimation printing are known for their durability, with designs that can withstand many washes without fading or cracking.

What is the most common t-shirt printing method?

Screen printing is the most common t-shirt printing method due to its cost-effectiveness and ability to produce durable prints.

Which is better: heat press or screen printing?

Screen printing is better for large orders and durability, while heat press is more versatile and easier for small, detailed designs.